Condensate Piping Design

Posted in Engineering

The next time you are on the roof, take a look at your condensate drains from the rooftop air conditioning units. You will be surprised that many of the drain lines are broken or do not have a “trap” in the piping.

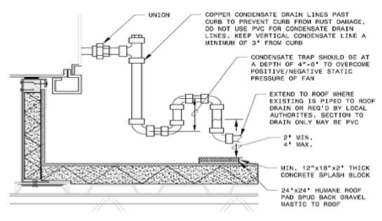

Why do you need a trap on your rooftop air conditioning unit? Most rooftop units are a draw through design, which means the supply fan is downstream of the cooling coil and condensate pan. The “P” trap creates a water seal preventing outside air from being drawn into the unit. If the trap is not installed correctly, the air entering through the trap will prevent the condensate from flowing out of the unit and will back up in the pan, potentially overflowing and leaking into the building. Also, the standing condensate in the pan may encourage bacteria growth.

The height of the “P” trap has been established by the manufacturer of the rooftop to block the conditioned air from discharging out of or drawing outside air in at the condensate connection. This height is based on the supply fan static pressure. If the rooftop manufacturer does not provide a “P” trap, their installation manual will provide the dimensions for the trap.

Some engineers’ designs or city codes require the condensate to be piped in copper that includes a clean out plug and unions, and some are even piped to the roof drain. Because of the scrap value of copper, some buildings have allowed this piping to be in PVC.

The problem with normal PVC is that it is not UV protected. After some years of exposure to sun light, the piping becomes brittle. If the pipe breaks from wind or a kick, you’re left without a trap. Two coats of a UV resistant paint may prevent the pipe from becoming brittle.

Do you remove your condensate trap in the winter to prevent freezing of the trap? If you go through this exercise, do you install a plug in the unit where you removed the trap? This will prevent cold air drawing into the unit. Remember to replace the trap in the spring.

Previous STORY

Previous STORY